Sustainability Report 2013: Investing in Physical Assets

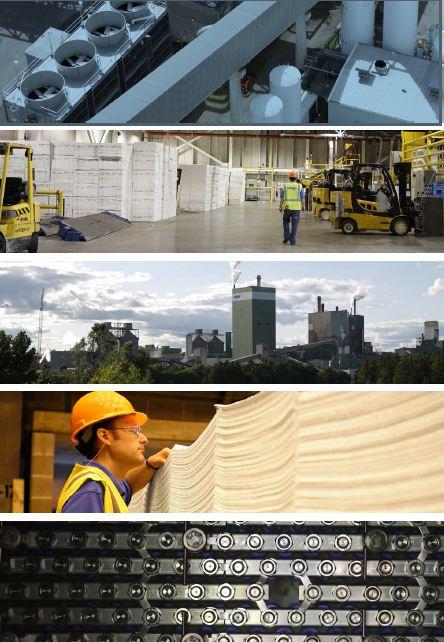

Since 2008, SFPNA has reinvested 84 percent of our operating income in capital expenditures.

SFPNA Sustainability Report 2013

These investments have resulted in product quality improvements, expanded capacity, increased operating flexibility, energy and material savings, as well as increased renewable energy production. In this past year, we completed major capital projects at each of our three manufacturing facilities in turn supporting all three of our business units. We are now well positioned for strong growth in the years ahead.

Pulp Mill Conversion

Over US $150 million dollars was invested in 2013 to modify the Cloquet Mill’s wood yard and pulping operations. The modifications enable the mill to produce dissolving pulp, a unique product that serves as a feedstock to textile and consumer goods (non-woven materials). Many of the changes were necessary to improve screening and cleaning as Sappi’s Specialised Cellulose has a lower tolerance for contaminants, many of which are naturally found in wood. The mill operates batch digesters and as part of the modification, two digesters were constructed (bringing the total to ten). An acid pre-hydrolysis stage was introduced along with an additional ozone bleaching stage. The pulp drying equipment also had to undergo modifications to accommodate the different fiber properties.

This investment, coupled with a similar conversion at Sappi’s Ngodwana Mill, brings Sappi Limited’s combined production capacity from 800,000 metric tons per year to over 1.3 million metric tons per year. Sappi is the market leader in providing pulp to the viscose staple fiber market segment and there is potential to enter higher value specialty markets in the future.

Coated Fine Paper Investments

We continue to outperform other North American coated paper manufacturers through our continued focus on market leading brands. Our product offerings are supported by strong technical service and ongoing research and development that help maintain low production costs.

The Somerset Mill successfully completed an upgrade to the forming section of our No. 3 paper machine (PM3) early in FY13. This US$13 million investment was implemented to improve formation with controlled drainage on both sides of the web. These improvements increase retention of materials and reduce defects that can cause holes and breaks on the machine. The successful implementation surpassed speed, efficiency and variable cost goals. The improvements also allow for a broader range of products to be made on the machine.

At our Cloquet Mill, Sappi invested US$14 million in coated papermaking assets, including a dry fiber handling system, as well as new refiners and an upgrade of our No. 4 paper machine (PM4). The rebuild of PM4 allows for all grades and weights to be manufactured with purchased (dry) fiber while maintaining the same base sheet formation and quality as products made with our own made slush fiber. The No. 12 paper machine at Cloquet will undergo a similar upgrade in FY14.

Coater Upgrade at Westbrook

In line with our diversification strategy, Sappi also made a US$2.5 million investment to rebuild an off-machine coater at our Westbrook Mill. This investment enables the mill to have higher productivity along with improved quality and operational flexibility.

In addition to our investments in physical assets, we continue to make strategic investments in our brands, our people, our business systems and intellectual property.

Investing in Research & Development

Sappi continues to support Research and Development facilities on three continents. With an annual budget of over US$30 million, over 25 percent of our R&D spend is dedicated to our “Exciter” program, which focuses on the development of breakthrough technology platforms. The bulk of R&D spend in the US is dedicated to product development efforts, primarily focused on coating materials. Within North America, our Technology Center in Westbrook, Maine, houses pilot coater equipment for two of our key businesses: release papers and coated wood-free papers.

R&D for pulping is centered in Southern Africa; however, with the conversion of our pulp mill in Cloquet, we expanded the technical support for the pulp business and added Specialised Cellulose quality testing lab facilities and staff at the mill.

In addition to our Technology Center, each mill has technical staff (primarily engineers) that focus on continuous improvement related to productivity gains, product enhancements, and resource conservation (energy, water and materials).

Read the full SFPNA Sustainability Report 2013 by downloading an online PDF version directly from our website here or for more on sustainability, check out our eQ microsite at: http://www.na.sappi.com/eQ/index.html